ELECTRONICS

-

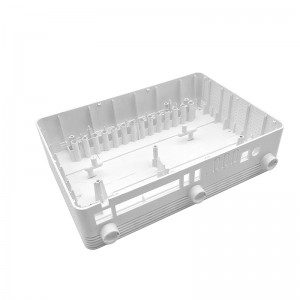

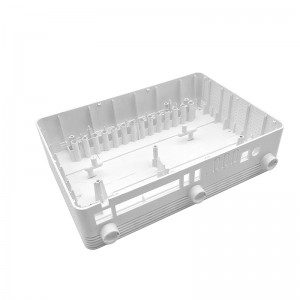

SET-TOP PLASTIC BOX

✭ This plastic part is the main part of the SET-TOP box, and it is the core part of the SET-TOP box.

✭ The material used for this plastic part is PC+ABS fireproof Materials, This is the appearance part of the overall structure, which carries all the structures of heat dissipation, interface, and PCBA.

✭ Its advantages are not easy to deform, good stability, high precision, to ensure that the set-top box has the characteristics of uniform heat dissipation and long service life during the working process.

✭ This mold is our company’s production mold, It specializes in mold manufacturing and injection molding production of housings for household appliances.. The production capacity of this set of molds is 1600 per day.

✭ If you have similar products, Please do not hesitate to contact us. Chapman Maker will be your best partner.

-

plastic glasses cover back

✭The plastic part is an important appearance and function part of the game glasses, and the appearance directly contacts with user. The plastic part is made of nylon PA12 (general), EMS Grivory TR90 (specification), color: black 9208.The mold for this plastic part is made with a two-plate mold. Because of the appearance and functional structure of the plastic parts, the mold design fully considers the external surface that can be protected and the principle of realizing the product function, and use the cold runner two submersible glue in an appropriate way. This method of injecting glue ensures the beautiful appearance of the product. , It can also improve the molding efficiency. The 2-point injection prevents the product from deforming due to the high injection pressure during the injection molding, and the size is unstable, which affects the product quality. This set of injection mold, our mold life is 500,000 shots. If you have similar products, please feel free to contact us. We will be your best partner.

-

Bank credit card POS machine

✭ This is a sealed plastic part inside the car, using high temperature and cold resistant PA66+30% plastic material. The working environment temperature of this part is between -40 and +100 degrees. It is resistant to outdoor weathering and meets Volkswagen’s 50185 standard.

✭ This plastic part is a part of a Oil filters Plastic ccessories from a Germany customer. The biggest difficulty of this part is that its wall thickness is only 0.45mm. This set of molds adopts the HASCO standard. The Core material is 1.2343 (ESR)hardened steel.

✭ The mold structure is relatively simple, with two Becu core inserts structures. The product material is PA6+30GF, and the surface needs to be VDI-24. Product size accuracy requirement is +/-0.05. The mold delivery time is 45 days, and the injection cycle is 12 seconds. The mold was tested only twice, and the customer asked us to arrange an export to the Germany injection molding factory.

✭ If you have similar products, Please do not hesitate to contact us. We will be your best partner.

-

Waterproof plastic case

✭This is a housing for electronic products, and the working environment is in water. Therefore, it is necessary to ensure a very high flatness and a high-quality waterproof level.

✭The material used for this plastic part is ABS-758 Materials, When placing the sealing ring, use 10 copper nuts to fix the upper and lower shells. Guarantee that the electronic parts in the housing will not be damaged. The 10 piece copper nuts is overmold in plastic molding, The firmness of the plastic and copper nuts is guaranteed.

Of course, in order to save the cost, we use a nut jig to improve the injection cycle during the injection molding process.

✭This transparent shell has very strict requirements on its flatness and appearance. The working life in water is guaranteed to be more than 10 years.

✭This mold is our company’s production mold, It specializes in mold manufacturing and injection molding production of housings for household appliances.. The production capacity of this set of molds is 1000 pieces per day.

✭If you have similar products, Please do not hesitate to contact us. Chapman Maker will be your best partner.

-

With PCBA plate mount part

✭ This is a plastic part used to fix the PCBA board, in order to keep the PCBA balanced and ensure the stability of the transmission signal. The requirements for this plastic part are very high, and the precision of the parts of the plastic product must be within 0.02mm. So, if several contact surfaces of the PCBA are fixed, the product cannot be draft angle, and the mold must be designed and manufactured in a Slider method.

✭ The high temperature resistant PC material used in this plastic material is a commonly used material for car lights. This material has the advantages of small deformation, good stability, high temperature resistance and cold resistance.

✭ This set of molds adopts the HASCO standard. The Core material is 1.2343 hardened steel. The mold structure is relatively complex structure, need to use exchangeable insert to production four different parts. The product material is PC, and the surface needs to be Polish 600. Product size accuracy requirement is +/-0.02. The mold delivery time is 38 days, and the injection cycle is 27 seconds. The mold was tested only twice, and the customer asked us to arrange an export to the Germany injection molding factory.

✭ If you have similar products, Please do not hesitate to contact us. We will be your best partner.