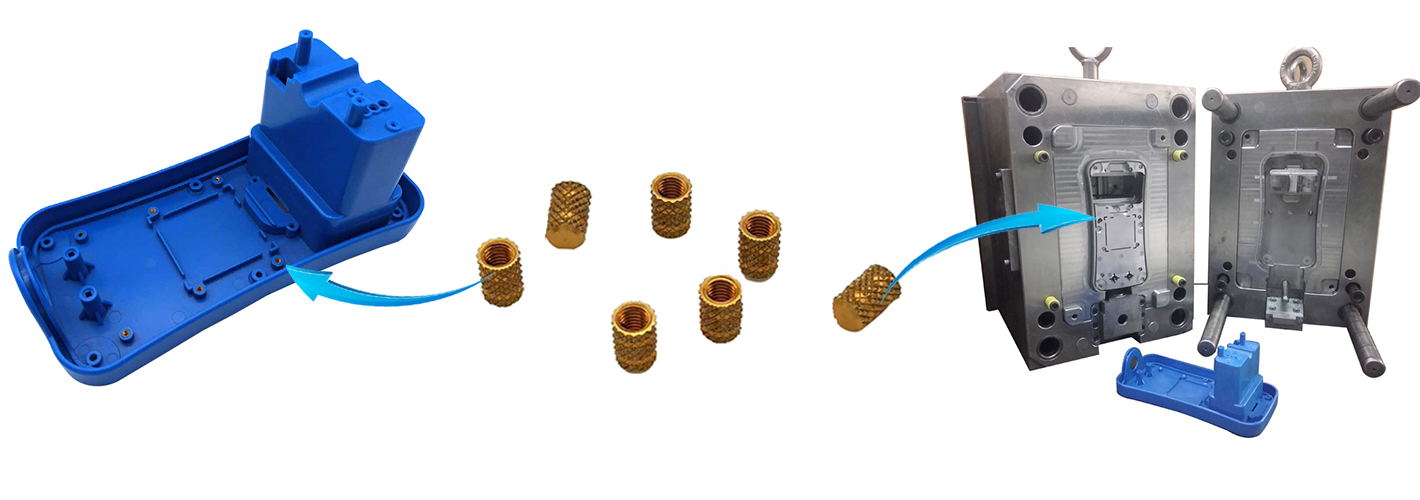

Insert molding is a process where thermoplastic resin is molded around another component. Often, metal components such as threaded inserts or fasteners are used in insert molding, but other components can also be utilized, like plastics, ceramics and other materials. There are many benefits of insert molding, including reduction in labor costs, reduction in part weight, improvements in quality, product functionality, and improvements in the overall component structure. Additionally, insert molding is more cost effective and an efficient solution for a complex assembly.

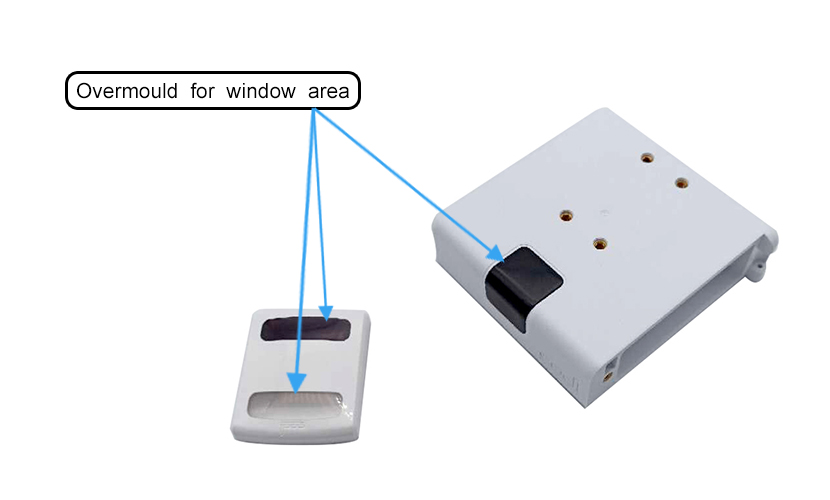

Similar to insert molding, the overmolding process involves thermoplastic resin being molded over or around another material, to form one solid component. Overmolding optimizes the production process of components with complex designs, overloaded assemblies, and detailed cosmetic aspects as it improves the bonding between the two resins.